A Crafter's Guide To Painting On Foam Core

Share

Transforming a simple sheet of foam core into a spectacular backdrop for a photoshoot or event is a rewarding project. Achieving that professional, flawless look is easier than you think and it all starts with choosing the right materials from the get-go. With the right approach, you can create stunning, durable pieces without the common frustrations of warping or bubbling.

The secret to success? It's all about using water-based acrylics and a quality primer to properly seal the board first. Let's dive into how you can master the art of painting on foam core.

Choosing Your Materials For Flawless Results

Getting a professional, lasting finish on foam core isn't just about painting technique; it's about having the right tools for the job. The material's construction—a polystyrene foam center sandwiched between two paper faces—is what makes it so light and affordable. But that paper is also what makes it vulnerable to moisture. Choosing the right supplies is the single most important step to ensure your project is a success.

Foam core has been a go-to for displays for a while now. Its popularity really took off in the early 2000s when digital printing made it easy for event planners to create vibrant, large-scale backdrops and retail displays. By 2010, its use in the North American events industry had jumped by over 40%. Why? Because it costs just 20-30% of what you'd pay for traditional wood or metal. You can see more about EVA foam's material properties in our post about ethylene-vinyl acetate foam.

Selecting the Right Foam Core

Not all foam core is the same, and the thickness and finish you pick will make a huge difference in your project's stability and final look. Before you even think about painting, you need to know what you're working with. For a deeper dive, this guide to understanding foam core board is a great resource.

- Standard vs. Acid-Free: For a backdrop for a one-day event, standard foam core is perfect. For artwork or displays you want to keep long-term, choose acid-free foam core to prevent the paper from yellowing over time.

- Thickness Matters: A standard 3/16-inch (5mm) board works well for smaller signs and crafts. But for large backdrops or anything freestanding that needs to resist bending, you'll want a thicker 1/2-inch board for that extra rigidity.

The key benefit of foam core is its versatility. Once you understand you're painting on paper glued to foam, you see why priming and light paint coats are the secrets to unlocking its full potential for any project.

Your Essential Paint and Tool Kit

Once you've got your board, it's time to gather your paint and tools. The main goal here is to get the color on without soaking and damaging the paper surface.

Paint Selection Guide For Foam Core

Choosing the right paint is simple with this quick comparison. Here are the benefits of each option for your foam core project.

| Paint Type | Best For | Pros | Cons |

|---|---|---|---|

| Water-Based Acrylic | General use, large backdrops, detailed craft work | Dries quickly, lightweight, low odor, easy cleanup | Can cause minor warping if applied too heavily without primer |

| Latex (House Paint) | Large-scale backdrops needing a matte finish | Excellent coverage, durable, available in many colors | Can be heavy and prone to cracking if the board flexes |

| Spray Paint (Acrylic) | Achieving a smooth, even coat without brush marks | Fast application, professional finish, great for stencils | Requires good ventilation, can oversaturate easily |

| Oil-Based Paint | Not Recommended | - | Solvents can dissolve the foam core, long drying time |

Ultimately, water-based acrylic paint is your safest and most versatile choice. It gives you great results without the risk of damaging your board.

Primers and Application Tools

A good primer is your project's best friend and your number one defense against warping.

- Primer: Gesso is a fantastic option. It's a thick, acrylic-based primer that creates a perfect seal on the paper. A quality spray primer is also a great choice for getting a thin, even coat down quickly.

- Applicators: For big, smooth surfaces, use a high-density foam roller—it’s the best way to avoid ugly brush strokes. When you’re doing more detailed work, a soft-bristled synthetic brush will give you the control you need without roughing up the paper.

How To Properly Prep And Prime Your Foam Core

Jumping straight into painting on foam core is tempting, but a little prep work is the secret to a professional outcome. Think of it like building a house—you need a solid foundation for everything to hold up.

Taking the time to prep your surface creates the perfect canvas for your paint to grab onto, ensuring the color goes on smoothly and stays put. Those few extra minutes at the beginning will pay off with a beautiful, durable final product.

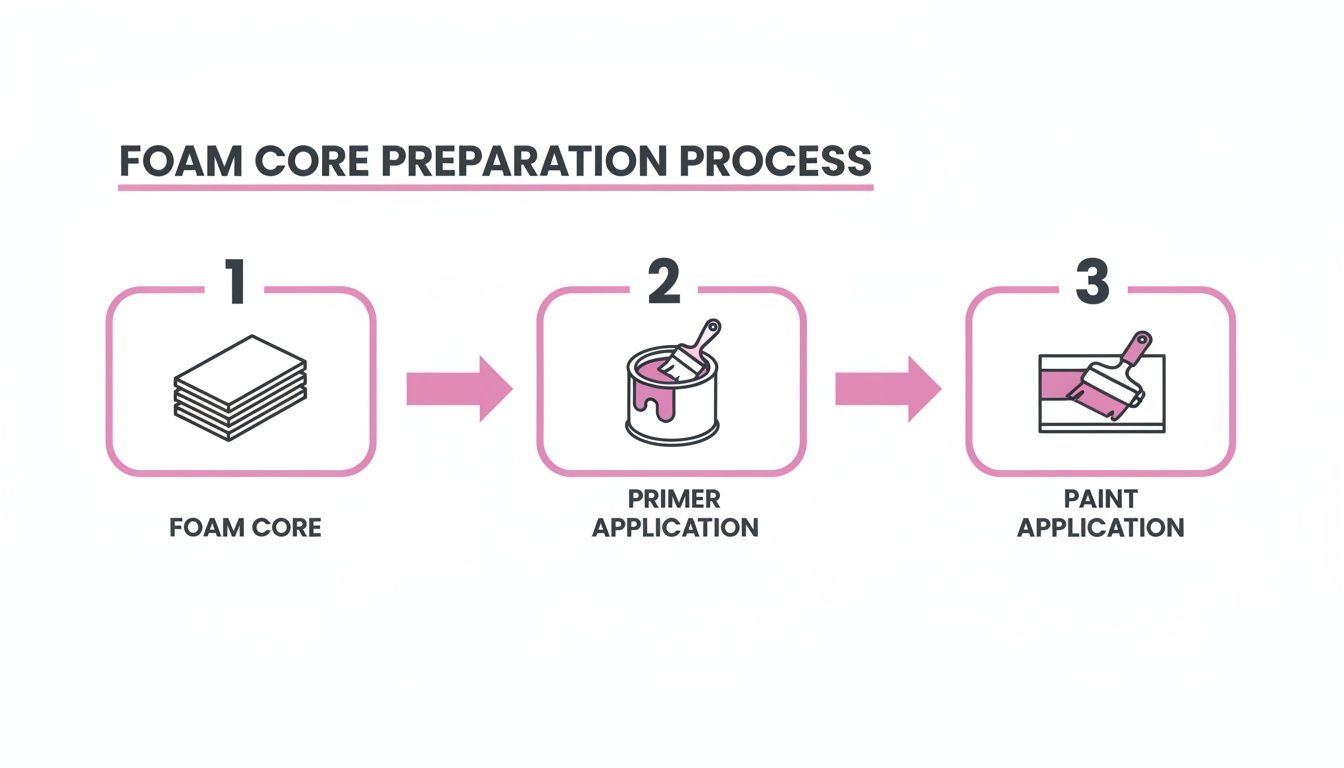

This simple workflow is the key: start with your board, seal it with a good primer, and only then are you truly ready to paint.

As you can see, priming isn’t just an extra step; it’s fundamental to getting a great result.

Create The Perfect Canvas: A 2-Step Guide

Your first job is to get the surface ready for that all-important primer. The paper face of foam core is quite smooth, so creating a little texture helps the primer get a solid grip.

- Gentle Sanding: Grab a piece of fine-grit sandpaper—something like 220-grit or higher—and lightly scuff the entire surface you plan to paint. You're not trying to tear through the paper, just rough it up enough for the primer to lock onto. This single action dramatically improves adhesion.

- Wipe Clean: Use a soft, dry cloth to wipe away any dust from sanding. Now your canvas is ready.

The Power of a Good Primer

Priming is the most important step for painting foam core. The paper surfaces will soak up moisture from water-based paint, which can cause swelling and warping. A good primer acts as a shield, sealing that absorbent paper and creating a stable, non-porous barrier between the foam and your paint.

You've got a few great options for this:

- Artist's Gesso: This is a fantastic choice. It's a thick, acrylic-based primer that gives great coverage and leaves a slightly toothy surface that paint loves. Apply a thin, even coat with a foam roller for best results.

- Spray Primer: For a perfectly smooth, factory-like finish, a can of matte spray primer is tough to beat. Just remember to hold the can about 10-12 inches from the surface and use light, sweeping passes.

- Latex Primer: If you have some quality water-based latex primer left over from a house project, that works well too. The key is to apply it thinly and evenly.

Here’s a pro tip: Always prime both the front and back of your foam core board, even if you only intend to paint one side. When primer dries, it creates tension. Priming both sides balances this tension, which is the secret to keeping the board perfectly flat as it dries.

A proper prime job also pays off in durability. For DIY crafters, foam core painted with acrylics can handle 500+ hours of outdoor exposure before fading, making it a surprisingly resilient choice for things like freestanding blooms in a retail display. The material's insulation properties have even led to a 15% rise in its use for festival installations between 2020 and 2025, where it has to hold up in varied climates.

Now that your board is properly prepped and sealed, you have a stable canvas ready for your creative vision. If you're weighing your options for other materials, you can check out our comparison of different types of foam for craft projects.

Mastering Your Painting Application Technique

Alright, your foam core is prepped, primed, and ready to go. You've basically built the perfect canvas. Now for the fun part—bringing it to life with color. The way you apply your paint is going to completely define the final look, so it's worth taking a moment to get it right.

This is a strategic choice. Each technique gives you a totally different finish, from something with a bit of organic texture to a surface that’s flawlessly smooth. The three main methods—brushing, rolling, and spraying—all have their place. Knowing when and how to use each is what turns a simple craft project into a professional-looking piece.

Use Cases for Each Technique:

- Brushing: Best for detailed artwork, fine lines, and small craft projects like flower petals.

- Rolling: Ideal for large, solid-color surfaces like event backdrops and signage.

- Spraying: Perfect for creating smooth gradients, stenciling, and achieving a factory-like finish.

Let's break down where each of these methods really shines, so you can nail that stunning, camera-ready result you're after.

Brush Application For Detailed Work

When your project demands precision, a brush is your best friend. The secret to a stroke-free finish is a soft-bristled synthetic brush. These are gentle on the primed surface and distribute paint evenly.

Steps for a Smooth Finish:

- Use Thin Coats: Apply your paint in several light layers. This prevents the board from getting too wet.

- Feather Your Strokes: Overlap your brushstrokes slightly and use a light touch. This technique helps blend any visible lines for a seamless look.

Roller Application For Speed And Coverage

For big projects like large-scale backdrops or event signage, a roller is your go-to. It’s incredibly efficient, covering a ton of surface area quickly and leaving a consistent, lightly stippled finish that looks fantastic on camera.

For the smoothest possible finish, grab a high-density foam roller. The dense foam creates minimal texture and doesn't soak up too much paint, which helps prevent the board from getting oversaturated.

Benefit for Event Planners: Switching to painted foam core backdrops can reduce setup times by as much as 35%. It's the perfect solution for creating quick-deploy photo ops that turn crowds into brand promoters, delivering real ROI through user-generated content.

Spray Application For A Flawless Finish

When you need that ultra-smooth, professional-grade finish with zero texture, it's time to reach for the spray can. This is the best way to create soft, beautiful gradients and use stencils for crisp designs.

Clear Steps for Spraying:

- Keep Your Distance: Hold the can about 10-12 inches away from the foam core to prevent pooling and drips.

- Use Sweeping Motions: Apply the paint in light, even passes, moving horizontally. Start spraying just before the edge of the board and stop just after the other edge to avoid splotches.

- Layer It Up: Multiple thin coats are always better than one thick one. Let each layer get a little tacky before applying the next to build up rich color gradually.

No matter which method you choose, don't forget that the shape of your project plays a big role. For some tips on creating custom shapes before you even think about painting, check out our guide on the best way to cut foam.

How To Dry, Cure, And Seal Your Painted Project

You’ve laid down that final, perfect coat of paint. It looks great! Now it’s time for the final, crucial steps. Taking the time to properly dry, cure, and seal your work is what makes the difference between a project that looks good and one that lasts, especially for event pieces that need to survive handling.

It’s easy to get these two mixed up, but knowing the difference between drying and curing is crucial. A painted surface might feel dry to the touch within an hour, but curing is the chemical process where the paint fully hardens and develops maximum durability, which can take days. Patience here is what guarantees a professional, long-lasting finish.

Creating The Ideal Drying Environment

Where you let your project dry is just as important as how you painted it. Your goal is a clean, low-traffic spot with a stable temperature and humidity.

Here’s how to set up the perfect drying space:

- Lay It Flat. Always place your painted foam core on a completely flat, level surface. Prop it up on small wooden blocks or painter's pyramids to get air circulating underneath and prevent sticking.

- Mind the Airflow. Gentle, indirect airflow is what you’re after. Avoid pointing a fan directly at the project, as this can cause uneven drying.

- Keep It Clean. Find a room where dust, debris, and pet hair won't be an issue. You can loosely tent a plastic sheet over the project if needed, just make sure it's not touching the surface.

Sealing For Protection And Longevity

Think of sealing as the armor for your project. This final layer provides a durable, protective shield for your painted foam core, guarding against scratches, moisture, and UV light. This is especially vital for items that will be handled or used outdoors, like the waterproof foam pieces in our DIY Giant English Rose kits.

The benefits of a good sealant include:

- Scratch Resistance: Adds a tough outer layer that can take minor scuffs and bumps during setup and transport.

- Moisture Barrier: Keeps humidity or a spilled drink from ruining the paper and paint.

- UV Protection: Stops harsh sunlight from dulling the vibrant colors you worked so hard on.

This durability is a huge reason why foam core is popping up everywhere in the events industry. While the building and construction sector accounted for 42.65% of engineered foam revenue in 2024, the events world is catching on fast, growing at a 5.32% CAGR. Event pros have found that custom-painted foam installations can slash costs by up to 25% while still looking incredible. You can dig into more of the data on how core materials are used across industries on coherentmarketinsights.com.

For event backdrops, I always recommend a matte spray varnish. It eliminates glare from flash photography, ensuring your piece looks perfect in every picture. A gloss finish might look striking in person but can create distracting reflections on camera.

The sealant you choose comes down to the look you want. You can find clear acrylic spray varnishes in matte, satin, or gloss finishes, or use a brush-on sealer like Mod Podge. The technique is the same: apply it in thin, even coats after the paint has fully cured. This final touch truly elevates your project to a professional grade.

Troubleshooting Common Painting Problems

Even when you do everything right, painting on foam core can sometimes present challenges. The good news is that most issues are common, totally fixable, and easy to avoid once you know the cause.

Most often, the issue comes down to how the paper facings on the foam core react to moisture. Let’s walk through how to diagnose and fix these common hiccups.

Fixing Warping and Bowing

Warping happens when one side of the board absorbs moisture from the paint and expands, while the dry side stays put. The fix is all about restoring balance.

Here are your solutions for warping:

- Proactive Fix: As covered earlier, priming both sides of the board is your best defense. This simple step balances the tension as the primer dries, keeping the board perfectly flat.

- Retroactive Fix: If your board is already warped, don't worry. Lightly mist the concave (unpainted) side with water or apply a thin coat of primer. Lay the board flat, place wax paper over it, and weigh it down with heavy, flat objects like books. Let it dry for a full 24 hours to flatten out.

Repairing Bubbles and Peeling Paint

Bubbles or peeling paint are signs that the paint isn't sticking properly to the primer. This usually happens if the primer wasn't fully cured or the surface had lingering dust or oils on it.

The key to a lasting finish is ensuring each layer—from primer to paint to sealer—is a team player. A small bubble is a sign that one layer isn't bonding with the one beneath it. Fixing it correctly ensures the whole system works together seamlessly.

Here's a step-by-step repair process:

- Isolate the Issue: Use a sharp craft knife to carefully cut around and remove the damaged paint.

- Feather the Edges: Lightly sand the edges of the remaining paint with fine-grit sandpaper (220-grit or higher) to create a smooth transition.

- Spot Prime: Apply a thin layer of primer to the exposed area and let it dry completely.

- Repaint: Carefully apply thin coats of your color, blending it into the surrounding area for an invisible fix.

Achieving Even and Opaque Coverage

Getting a solid, even color can be tricky. The key is to avoid applying one thick coat.

Patience and layering are your best friends here. It is always better to apply three thin, even coats than one thick, heavy one. Let each layer get tack-free before you add the next. This method gradually builds up a rich, opaque color without oversaturating the paper.

The ability to achieve seamless color matching is a huge benefit for event professionals. For wedding planners, historical data shows that foam core installations boosted venue photo shares by 28% during peak seasons. As event organizers become more eco-conscious, innovations in bio-based and recycled foams are also gaining traction. You can find more details on this trend and the growing industrial foam market on towardspackaging.com.

Common Questions About Painting Foam Core

Now that we've walked through the core techniques, let's tackle some of the specific questions that pop up most often. I've gathered the most common queries we get from creators to help you get straight to the fun part.

What Kind of Paint Should I Use on Foam Core?

For the best results, stick with water-based acrylic paints. They are low odor, quick to dry, easy to clean up, and won't damage the foam core.

Avoid heavy, solvent-based paints like traditional oil paints or industrial enamels. The chemical solvents can dissolve the polystyrene core.

No matter what acrylic you use, priming is non-negotiable. Always start with a water-based primer to seal the paper surface. This one step is your best defense against moisture and warping.

How Is Painting Foam Core Different From Painting EVA Foam?

This is a great question, and the answer comes down to their fundamental structures. Knowing the difference will help you pick the right material for your project right from the start.

- Foam Core is a rigid sandwich: a sheet of polystyrene foam between two layers of paper. You're really painting on paper, which is why primer is crucial to block moisture. Because it's rigid, the paint will crack if you bend it.

- EVA Foam, which we use in all our Amazing Giant Flowers kits, is a dense, flexible, closed-cell foam that’s naturally non-porous. You don't need to prime it for water resistance, and you can heat-shape it into curves. Paint on EVA foam flexes with the material, making it perfect for durable, 3D art.

The easiest way to think about it is this: Foam core is your go-to for flat, rigid pieces like signs and backdrops. EVA foam acts more like a flexible fabric, ideal for building sculptural pieces like our giant flowers that need to bend and hold their shape without the paint cracking.

What’s the Best Way to Stop Foam Core From Warping?

Warping is almost completely preventable. It happens when the paper layers absorb moisture unevenly.

Here are the best prevention methods:

- Seal the Entire Board: The single most effective trick is to apply a thin, even coat of quality primer like gesso to the front, the back, and all exposed edges. Let it dry completely.

- Use Thin Coats of Paint: Apply your paint in several thin layers instead of one thick coat. This dramatically cuts down on the amount of moisture hitting the board at once.

If you still see a slight curve, you can often flatten it out by laying the board under a stack of heavy books while it finishes drying.

How Can I Get Super Clean, Crisp Edges?

For razor-sharp lines and perfect geometric patterns, good painter's tape is your best friend. Use a tape made for delicate surfaces to avoid peeling off the foam core's paper layer.

Here’s a foolproof method for perfect lines:

- Lay down your tape and run a fingernail or a credit card along the edge to get a tight seal.

- The Secret Step: Paint a thin layer of your base color (or a clear sealant) right over the tape's edge. This fills any microscopic gaps so your new color can't bleed underneath.

- For the cleanest reveal, pull the tape off slowly at a 45-degree angle while the paint is still just a little damp.

If you're looking for more materials and ideas, feel free to browse our curated collection of flower-making supplies.

Ready to build your own show-stopping creations? At Amazing Giant Flowers, we have everything you need to bring your vision to life, from complete DIY kits to stunning custom installations. Explore our collection and start making something unforgettable at https://www.amazinggiantflowers.com.

Built with Outrank tool