The Best Way to Cut Foam for Flawless DIY Crafts

Share

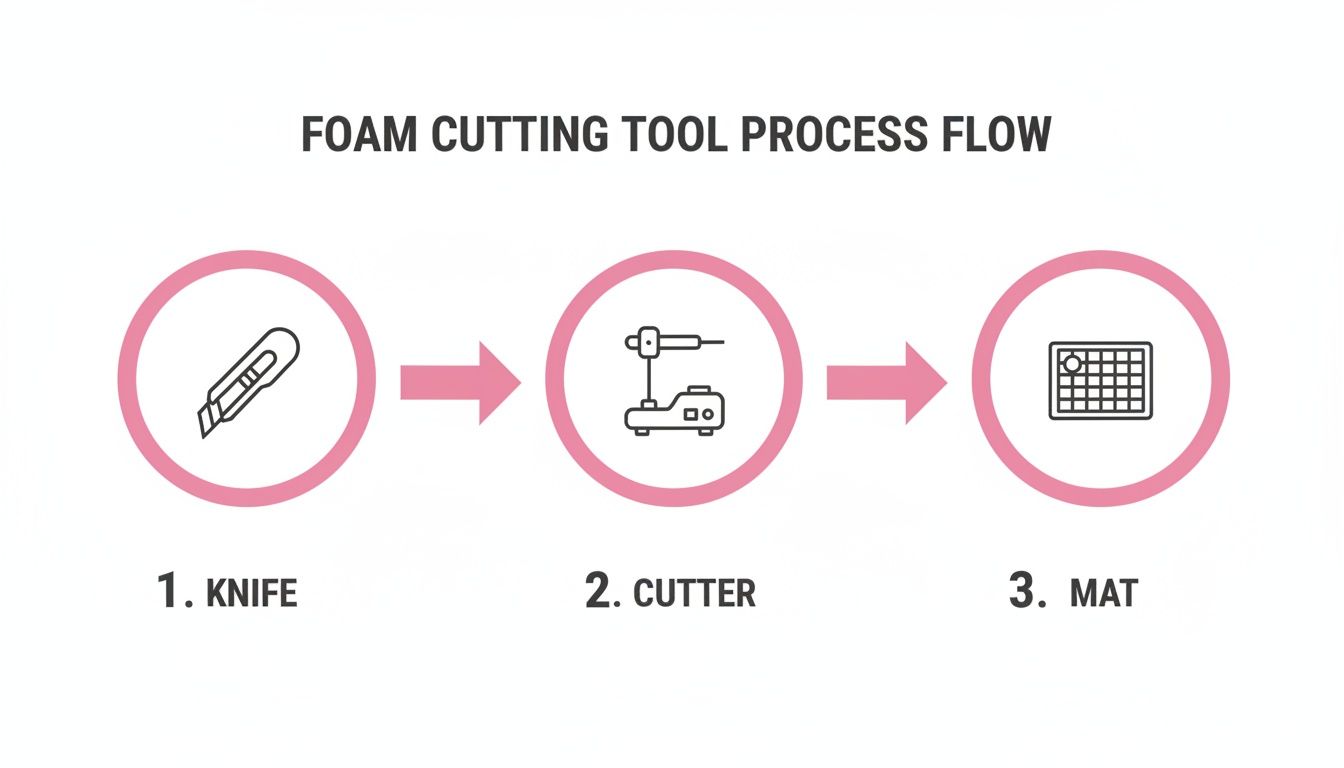

To create stunning, professional-looking giant flowers, you must master the art of the cut—it's the single most important first step. For crafters working with standard EVA foam, the solution is simple and effective: a sharp, heavy-duty utility knife. It provides the best combination of control and cost-effectiveness for creating intricate petal shapes.

However, if your project involves much thicker foam or you're scaling up production, a hot wire cutter could be your new best friend. It delivers perfectly sealed, clean edges that a traditional blade simply can't replicate.

Why a Perfect Cut Is Everything for Giant Flowers

When you're crafting giant foam flowers, the quality of your cut lays the groundwork for the entire project. It's what separates a project that looks "homemade" from one that looks like a professional, artistic installation. A clean cut is about more than just aesthetics—it’s about precision and durability, ensuring your creation is both beautiful and long-lasting.

Think of it like tailoring a custom suit. If the initial fabric cuts are even slightly off, the seams will never line up, the garment won’t hang right, and the whole thing will look amateur. The same exact principle applies to your foam creations.

Benefits of Mastering Foam Cutting

Getting a clean, precise cut from the start saves you a world of headaches down the line. It allows you to focus on the fun part—the artistry—instead of struggling with difficult assembly. The benefits are immediate and impactful.

- Flawless Assembly: Petals and leaves with smooth, straight edges glue together perfectly. This creates stronger bonds and makes your seams practically invisible.

- Professional Finish: A crisp cut is the secret to a polished, high-quality flower, whether it’s destined for a wedding backdrop or a chic retail display.

- Enjoyable Process: When you eliminate torn foam and jagged lines, the whole process becomes more enjoyable and efficient. You save time and materials.

- Realistic Results: Perfect cuts allow you to create the delicate, natural curves and sharp points that mimic real flowers, taking your final piece to a new level of realism.

This guide is all about moving past frustrating, jagged edges. You'll learn the techniques that elevate your work from a simple hobby to a true art form. We’ll get into both manual and automated methods, giving you the know-how to choose the best way to cut foam for any project you can dream up.

Picking the Right Tools for Cutting Foam

Getting a clean, professional cut in foam all comes down to using the right tool for the job. This is the secret behind those flawless, crisp edges you see on high-end giant flower displays. The right tool saves you time, prevents you from wasting expensive foam, and makes the entire process more enjoyable.

It’s not as simple as just grabbing whatever is sharp. You have to match the tool to the foam's density and the kind of shape you’re trying to create. This is where you really level up from just crafting to creating true art.

Your Manual Cutting Tool Checklist

For most creators making giant flowers out of EVA foam, manual tools offer the best mix of control, precision, and affordability. You don't need an expensive workshop to get started—just a few reliable basics.

- Heavy-Duty Utility Knife: This is your absolute workhorse. Look for a sturdy, retractable model with a comfortable grip. Snap-off style blades are excellent because you can get a brand-new, razor-sharp tip in seconds.

- Precision Craft Knife: For tight corners and intricate details like leaf veins, a smaller blade like an X-Acto knife provides superior control and maneuverability.

- A Supply of Fresh Blades: This is non-negotiable. A dull blade doesn't slice foam; it tears and compresses it. Always start a new project with a fresh blade and snap off a new segment the moment you feel any drag or resistance.

Use Cases for Specialized Foam Cutters

As your projects grow in size or complexity, specialized tools can dramatically speed up your workflow and provide a finish that’s tough to achieve by hand.

- Hot Wire Cutters: A go-to for serious creators, these tools melt through foam to create a perfectly sealed, smooth edge. They are ideal for thick foam bases or internal structural pieces. The foam cutting machine market hit USD 164.80 million around 2023 and is projected to climb to USD 306.40 million by 2033, with hot wire cutters being a significant part of that growth. They offer incredible precision and can reduce material waste by up to 25%.

- Hot Knives: Similar to hot wire cutters, these handheld tools also melt the foam. They are excellent for freehand shaping and carving thicker foam blocks.

Essential Workspace Accessories for Success

Your cutting tools are only part of the story. The right accessories are just as important for safety and accuracy.

- Self-Healing Cutting Mat: This is indispensable. It protects your blade from dulling and saves your work surface. The grid lines are a lifesaver for keeping everything perfectly aligned.

- Metal Ruler with a Cork Back: The metal edge provides a solid, straight guide for your knife. The cork backing is a game-changer, preventing the ruler from slipping on the foam.

- Safety Gloves: A pair of cut-resistant gloves provides peace of mind, especially when applying pressure to cut through thicker foam.

- Good Ventilation: This is critical when using a hot knife or hot wire cutter. Melting foam can release fumes, so always work near an open window or use a fan.

Once you have your tools and accessories ready, you’re all set. The last piece of the puzzle is the foam itself, and you can find fantastic, versatile options like these EVA foam rolls perfect for crafting.

Mastering the Cut for Every Foam Shape

Once your tools and workspace are ready, it's time to cut. This is where skill and technique separate amateur-looking crafts from truly professional pieces. Learning to guide the blade with confidence is what creates clean edges and perfect shapes, whether you're slicing a long stem or shaping a delicate rose petal. The best way to cut foam isn't just about having a sharp knife; it's about understanding how to move the blade through the material.

Steps to Nailing Perfectly Straight Lines

For giant flower stems or geometric backdrops, a perfectly straight cut is non-negotiable. Here’s how to achieve it, especially for foam thicker than 3mm:

- Anchor Your Guide: Press down firmly on a metal ruler with a cork back to prevent any slips.

- Make the First Pass: Hold your blade at a perfect 90-degree angle and make a shallow first cut. Use only the tip of the blade to create a guide channel.

- Deepen the Cut: Go back over your line, sinking the blade a little deeper. It will naturally follow the channel you just made.

- Complete the Cut: A third pass should cleanly separate the two pieces. This multi-pass technique prevents the blade from bending and dragging the material.

For thinner foam (around 1-3mm), you can often use a "score and snap" method: lightly drag your blade along the ruler to score the surface, then gently bend the foam along that line until it snaps cleanly.

Creating Elegant, Natural Curves

Curves are the soul of a giant flower, defining the soft, organic look of every petal. The key to a smooth arc is to move the foam, not just the knife.

- Technique: Keep your cutting hand and wrist relatively stable. Use your other hand to slowly rotate the foam sheet into the blade. This creates a more fluid and controlled motion.

- Consistency: Maintain a consistent angle and pressure as you cut. Think of it like tracing a line with a fine-point pen—sudden changes will disrupt the curve.

- Practice: Grab some scrap pieces of large EVA foam craft sheets and practice cutting "S" and "C" curves to build muscle memory.

Adding Dimension with Bevels and Chamfers

Angled edges, known as bevels and chamfers, add incredible depth and help petals nestle together more naturally. This subtle detail makes a world of difference in the final product. To create one, hold your blade at an angle—a 45-degree angle is a great place to start—instead of perpendicular to the foam.

Use Cases for Angled Cuts:

- Petal Edges: A slight bevel along the edge makes a petal look thinner and more delicate.

- Leaf Veins: Score shallow, V-shaped grooves with an angled blade to mimic the look of natural leaf veins.

- Layering Petals: Beveling the edge of a lower petal allows the top piece to sit more flush, creating a seamless transition.

How to Cut Thick Foam Without Jagged Results

Cutting through thick foam (10mm or more) can be intimidating. The main challenge is blade drag, where friction causes the blade to bend and tear the foam. The solution is a methodical, multi-pass technique.

- Extend Your Blade: Ensure enough blade is extended to pass completely through the foam’s thickness.

- Make a Guiding Cut: Start with a very shallow first pass (1-2mm deep) to establish a clean, straight line.

- Go Deeper in Stages: On each subsequent pass, sink the blade about a quarter of the way deeper into the foam. Let the blade do the work without forcing it.

- Stay Perfectly Vertical: The hardest part is keeping the blade straight up and down through all passes to ensure the edge is truly square.

Scaling Up with High Volume Cutting Solutions

For professional crafters and event planners, there comes a point where cutting by hand is no longer efficient. When you need hundreds of identical petals for a massive brand activation or an unforgettable wedding backdrop, consistency and speed are everything. Automated cutting systems eliminate the inconsistencies and slow turnaround times of manual work, delivering the reliability you need for large-scale projects.

The Power of CNC Foam Cutting

A CNC (Computer Numerical Control) foam cutter is a game-changer. It takes a digital design file and translates it into perfectly executed physical cuts with incredible accuracy. You can design the most intricate petal imaginable, and the machine will reproduce it flawlessly every time.

According to Verified Market Research, this technology is a key reason the foam cutting machine market is growing rapidly.

Benefits of CNC Cutting:

- Flawless Consistency: Every piece is a perfect twin of the digital file, ensuring a polished, professional look across your entire display.

- Massive Time Savings: A job that would take days by hand can be completed in hours, freeing you up for assembly and finishing.

- Reduced Material Waste: CNC software intelligently arranges shapes to maximize foam usage, a process known as "nesting," which saves money.

- Complex Designs Made Easy: Intricate patterns or company logos that are nearly impossible to cut by hand are handled effortlessly.

Accessible Alternatives for Growing Businesses

A full industrial CNC machine is a serious investment. For businesses just beginning to scale, more accessible options offer automated magic without the hefty price tag.

Use Case: Die-Cutting Machines

- The Scenario: You land a gig creating 50 elaborate centerpieces, each requiring 20 identical leaves. That’s 1,000 leaves to cut by hand!

- The Solution: An electronic die-cutting machine can automate this entire tedious process. These machines are surprisingly capable of handling thinner EVA foam and are workhorses for churning out smaller, repeatable shapes.

- The Outcome: You get perfectly uniform leaves while you focus your energy on shaping the larger, more prominent petals.

When you're ready to feed a bigger machine, materials like these large-format EVA foam rolls are perfect for scaled-up production.

Troubleshooting Common Foam Cutting Problems

Even with the best tools, cutting foam can sometimes be frustrating. You might follow all the steps and still end up with a wavy line or a ragged edge. Fortunately, these issues are almost always fixable. Knowing how to cut foam isn't just about the initial technique—it's also about knowing how to diagnose and solve problems as they arise.

Solution Steps for Wavy or Uneven Lines

A wavy cut is a common headache, but it usually comes down to technique, not the tool. The culprits are often inconsistent pressure or a poor blade angle.

Here are the steps to fix this instantly:

- Check Your Grip: Don't hold the knife in a death grip. A relaxed hand allows for a much smoother cutting motion.

- Verify Your Angle: Ensure your blade is at a perfect 90-degree angle to the foam's surface. A slight lean will cause the blade to drift.

- Use Long Strokes: Ditch short, sawing motions. A single, long pass is always cleaner. For thicker foam, repeat with multiple long, steady passes.

How to Solve Tearing and Jagged Edges

A torn, shredded edge can ruin the look of a flower petal and make assembly impossible. The number one cause is a dull blade. Foam, especially Ethylene-Vinyl Acetate foam, demands a razor-sharp edge to slice cleanly.

- First Action: Before anything else, snap off the old blade segment or swap in a fresh one.

- Check Pressure: Pushing down too hard squashes the foam before it's cut, causing it to tear. Use lighter pressure and build up your cut with several shallow passes.

- Pace Yourself: Rushing a cut can cause the blade to skip and tear the foam. Slow down and focus on a steady, controlled pace.

Steps to Smooth Out Fuzzy or Rough Edges

Sometimes, a technically perfect cut can still leave a slightly fuzzy texture. Cleaning this up is a simple finishing step that elevates your project from "good" to "great."

Effective Finishing Techniques:

- Gentle Sanding: Use a fine-grit sanding block or an emery board to lightly smooth the edge. The goal is to knock down the fuzz, not reshape the piece.

- Heat Sealing: For a pro-level finish, make a quick pass with a heat gun held at a safe distance. This slightly melts and seals the foam's open pores, creating an incredibly smooth edge that’s perfect for painting. Always practice on a scrap piece first.

Your Top Foam-Cutting Questions Answered

Even with the best techniques, specific questions often come up. Nailing these details can help you move past frustrating hangups and start producing clean, professional work every time.

What's the Absolute Best Knife for Cutting EVA Foam?

For most EVA foam projects, the champion is a standard, heavy-duty utility knife. The magic isn't in a fancy brand—it's all about sharpness. A brand-new blade glides through foam, leaving a perfect edge. For intricate curves on thinner foam (2-5mm), a craft knife like an X-Acto provides extra control.

Pro Tip: Always start a new project with a fresh blade. The second you feel any resistance, swap it out. A dull blade is the #1 cause of messy cuts.

How Do I Stop My Cuts from Looking Jagged or Wavy?

Getting smooth, clean lines is totally achievable. Run through this quick checklist to diagnose the issue:

- Check Your Blade Angle: Is your knife perfectly perpendicular (a 90-degree angle) to the foam?

- Use Long, Confident Strokes: Avoid short, sawing motions. Aim for one long, continuous cut with steady pressure.

- Secure Your Materials: Use a metal ruler for straight lines and hold your foam firmly on a non-slip cutting mat.

- Try the Multi-Pass Method: For thicker foam, make two or three shallow passes instead of one deep, forceful cut. This reduces drag and prevents tearing.

Can I Just Use Scissors to Cut My Flower Petals?

While tempting, scissors are not recommended for the thicker EVA foam used in giant flower making (3mm and up). Here’s why this is a common paint point for beginners:

- The Problem: Scissors compress the foam as they cut. This pinching action creates a rounded, beveled edge instead of the clean, flat, 90-degree surface you need for strong seams.

- The Result: A beveled edge is difficult to glue neatly, often leading to visible gaps and distorting the beautiful shape of your petals.

- The Solution: For a professional finish with strong, invisible seams, a sharp blade is always the best way to cut foam. It gives you the perfect, square edge essential for building durable giant flowers.

Ready to turn your creative vision into a breathtaking reality? At Amazing Giant Flowers, we offer the highest-quality EVA foam, complete DIY kits, and expert tutorials to help you create unforgettable floral installations. Whether you're an event pro, a brand marketer, or just a passionate creator, we have everything you need to succeed.

Explore our collection of giant flower kits and premium crafting supplies today!

Prepared with Outrank app